Consumables catalog

How to choose consumables correctly

One of the most common abrasive materials is the wheel. Abrasive wheels are simple and compound. Consequently, the former are a simple and uniform abrasive, while the latter are known as disc-shaped. The name comes from the shape of the steel base, which looks like a plate. At the same time, diamond spraying is applied to the discs. They can be conical and cylindrical.As a rule, abrasive wheels are classified according to grit size, hardness, maximum rotational speed and accuracy class. When choosing, you should also pay attention to the size of the abrasive grains, since the frequency of metalworking depends on it. Hardness is responsible for the wear and tear of the machine and its performance. Pay attention to the maximum rotation speed, because the frequency of the rotation circle depends on it without the risk of collapse. Finally, the accuracy class is responsible for the compliance of the geometric parameters of the tool with the characteristics specified in the passport.

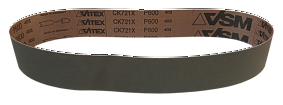

Sanding belt is another type of consumable that is used in belt sander machines. The tapes differ among themselves in material, width, grain size, as well as connecting seams. In addition, sanding belts are divided according to the type of equipment: designed for hand-held machines, narrow belt machines and sanding skins. When choosing such a material, one should take into account the characteristics of the material being processed. So, if you need to process a dense surface, then tapes with large grains should be used.

You can get help in choosing belts and other abrasive materials from ADEMS consultants. At the same time, you can buy abrasive materials from us at a very reasonable price. So, the cost of grinding wheels varies from 19 cents, the price of grinding belts starts from 82 cents.